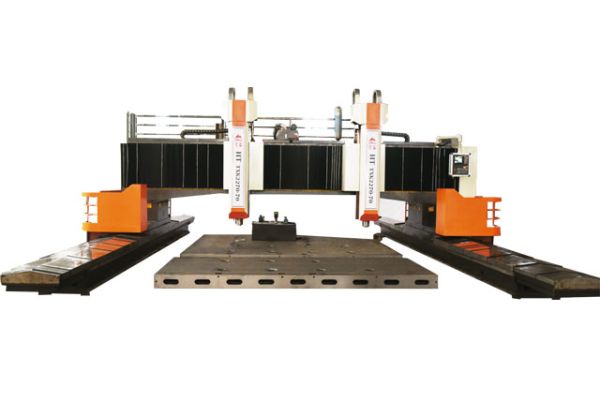

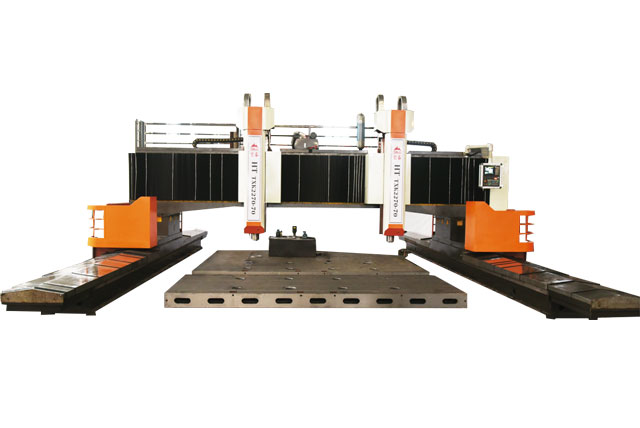

Machine tool use

ZXK fixed beam gantry mobile drilling and milling machine, mainly used for large flanges, bearings, pipe fittings, various metals and their alloys, non-ferrous metals, non-metallic materials for drilling, rigid tapping, thread milling, reaming and other materials, can also be used for milling, hole, boring processing under the appropriate cutting parameters, with milling, drilling (drilling, expanding, reaming) and other processing functions.

This machine tool is mainly composed of bed and column, beam and transverse slide table, vertical ram, drilling and milling power head, workbench, chip removal, hydraulic system, cooling system, centralized lubrication system, electrical system, etc.

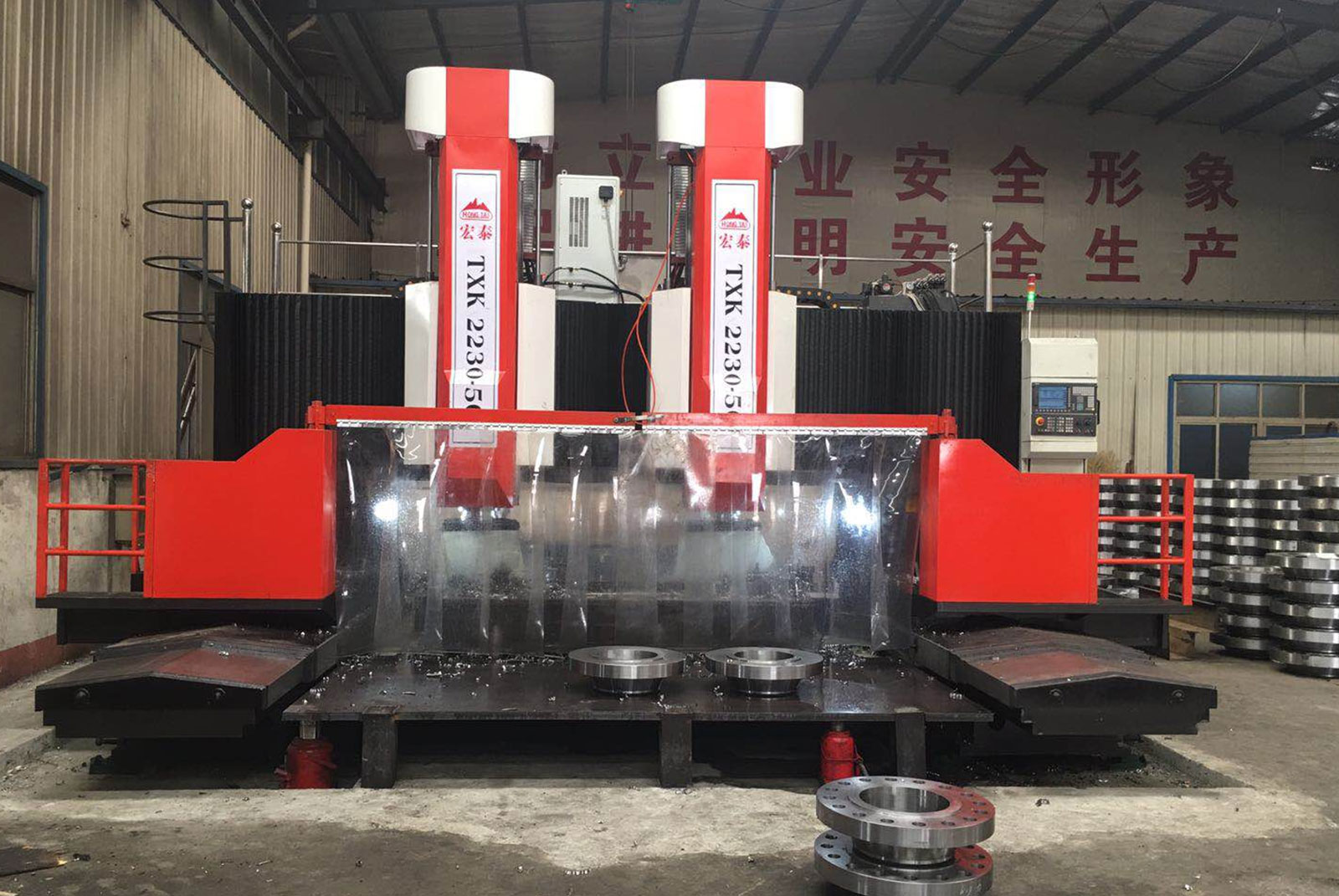

Main structural properties and characteristics

1. Machine bed, column, beam, table, slide plate, ram, etc. are made of castings, finished after secondary annealing and vibration aging treatment, with good static and dynamic rigidity.

2. The X and Y axes are composed of heavy rolling linear guide rail + and static pressure hard guide rail.

3. Z-axis adopts hard guide rail, four sides large tolerance, square ram structure.

4.X, Y, Z three axes are driven by imported precision ball screw to ensure transmission accuracy.

5. The drilling power head adopts full-gear high-low two-speed transmission, which drives the spindle to rotate after decelerating and increasing the torque, and has sufficient power and wide speed regulation.

6. Spindle center water function, equipped with cutting fluid filtration system, effectively filter and cut impurities in the coolant.

7. Equipped with automatic lubrication device, it can automatically lubricate the moving pairs such as guide rail and lead screw everywhere.

8. The key parts of the machine tool are supplied by well-known manufacturers at home and abroad to ensure the reliability and stability of the machine tool.

Main technical parameters

| Equipment type | ZXK40-40 | ZXK50-50 | ZXK60-60 | ZXK70-70 | ZXK80-80 |

| Maximum machining size (X axis *Y axis) | 4000*4000 | 5000*5000 | 6000*6000 | 7000*7000 | 8000*8000 |

| Slider vertical up and down travel Z axis (mm) | 700 | 700 | 1000 | 1000 | 1000 |

| Distance between spindle milling surface and worktop (mm) | 200-900 | 200-900 | 200-1200 | 200-1200 | 200-1200 |

| Spindle cone pass number | BT50 | BT50 | BT50 | BT50 | BT50 |

| Large machining diameter (mm) | φ96 | φ96 | φ96 | φ96 | φ96 |

| Maximum tapping diameter (mm) | M30 | M30 | M36 | M36 | M36 |

| Spindle speed (r/min) | 30-3000 | 30-3000 | 30-3000 | 30-3000 | 30-3000 |

| Spindle motor Power (KW) | 22/30/37 | 22/30/37 | 30/37 | 30/37 | 30/37 |

| Positioning accuracy: X, Y, Z (mm) | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

| Repeated positioning accuracy: X, Y, Z (mm) | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| Numerical control system | Fanuc/Siemens/Kainty | ||||

| Tool capacity (optional) | 24 pan knife library, 40, 60, 80, 120 chain knife library | ||||