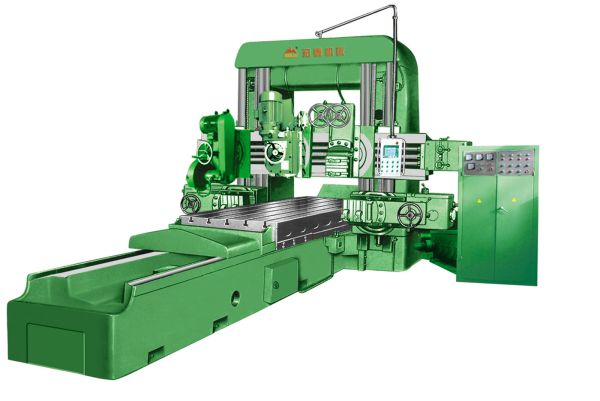

TBXM20 series gantry milling machine is developed on the basis of the gantry planer technology of Jinan Second Machine Tool Group Co., LTD. The series of machine tools are universal, high degree of standardization, more advanced technology, more reasonable structure, more simple operation. Z4 DC motor and British Parker 590 full digital speed control system, more energy saving. Imported PLC programmable control and 5.7-inch color touch screen display, to achieve high digital precision, good rigidity, boring, milling, planing, grinding four in one, is your ideal processing equipment.

Main structural properties and features:

● Bed, workbench, gantry frame, beam and other large parts are made of resin sand casting process. The stress of casting was eliminated by thermal aging treatment and vibration aging treatment.

All guide surfaces are quenched. The straightness, flatness, verticality and parallelism of each datum plane are tested by laser measuring instrument and meet the technical requirements.

● The bed, workbench, main drive gearbox, etc., adopt centralized lubrication.

● Cross beam vertical feed box, left and right side slide plate feed box are driven by AC servo motor, accurate feed, tool holder, milling head, grinding etc. can be automatic or manual, flexible operation.

The work table reducer adopts Z4 DC motor and British Parker 590 full digital speed regulation system and planing, milling and grinding process becomes easy, stepless speed regulation, instant efficiency and energy saving, stepless speed regulation can be achieved, and can meet the processing requirements of planing, milling and grinding.