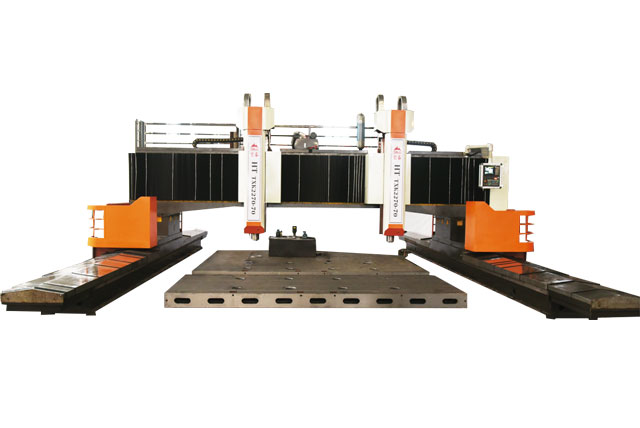

Gantry drilling machine is a horizontal CNC drilling machine with gantry frame and three spindles. Can process three parts at the same time, high production efficiency. The equipment can be used in steel, stainless steel, titanium, nickel, zirconium, tantalum, Monel, Hazelloy and other simple materials, as well as titanium/steel, nickel/steel, zirconium/steel, tantalum/steel, stainless steel and other composite materials production, to achieve drilling, reaming, reaming, drilling blind holes, inner hole cutting (using special auxiliary tools) and other functions, drilling with ordinary twist drill.

Gantry drilling machine is mainly composed of bed table, moving gantry, longitudinal sliding table, drilling power box, CNC sliding table, automatic chip removal and circulating cooling device, electrical system and so on.

1, bed table:

The bed is composed of 900 wide, 5410 long and 800 high, and the left, middle and right sections of the main bed are connected with the bridge section. The total width is 4560, welded steel structure, after manual aging treatment. The gantry drilling machine work table is installed with 16 plates, the top of the T-groove, groove width 28, easy to install the workpiece. On the left and right sides of the bed, each side is arranged with two linear rolling guides and precision ball screws, the distance is 450, the length is 6410, for the movement of the longitudinal slide of the gantry. Adjustable bolts are distributed on the bottom surface of the gantry drilling machine body, which can easily adjust the height of the bed table.

2, mobile gantry:

The gantry frame of the gantry drilling machine is 5550 wide and 1726 high, and is assembled by steel plate with artificial aging. There are two large-capacity linear rolling guides with a distance of 650 and a length of 4550 on the front side of the gantry, and two sets of precision ball screws and AC servo motors are installed on the top to make the three power heads move in the Y direction. A drilling power box is installed above each power head slide, and a drill bit can be installed on the main shaft. Both sides of the power head slide board of the gantry drilling machine are equipped with flexible protective covers of guide rails.

3. Longitudinal guide rails

The longitudinal slide board is a right-angle curved plate welded steel structure, distributed left and right. Two belt wheels with 2kW AC servo motors and a transmission ratio of 2 are installed on the vertical surface of the left and right longitudinal sliding table of the gantry drilling machine. The small pulley is installed on the spindle motor, the large pulley is connected with the ball nut, and the servo motor is driven by the pulley. The ball nut rotates on the ball screw to drive the slider to move on the rolling guide rail. When loading and unloading work pieces, the two power heads can be moved to both ends of the gantry drilling machine to facilitate workpiece loading and unloading.