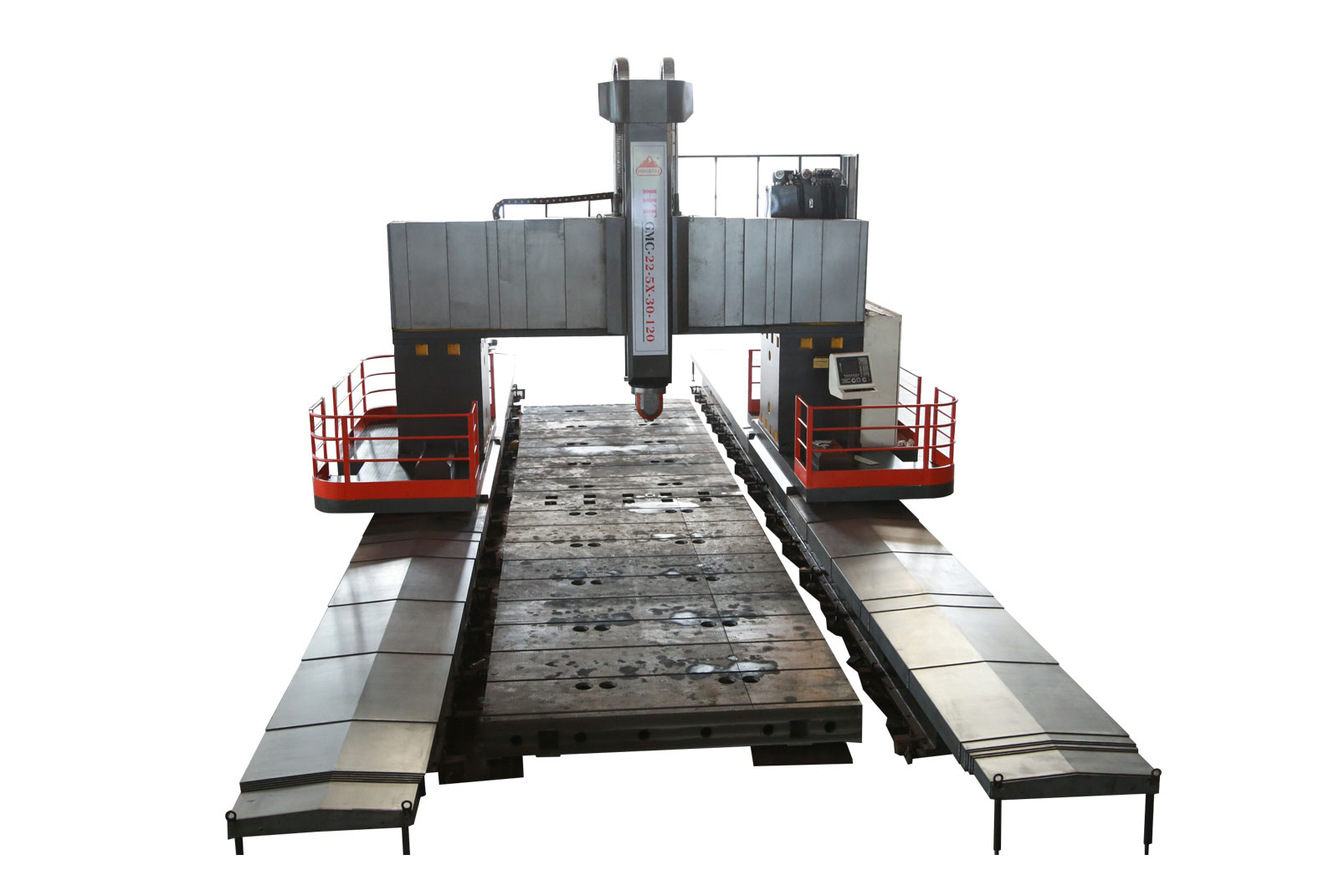

The gantry drilling machine is mainly composed of the bed, worktable, gantry, sliding plate, power head, CNC system, cooling and chip removal system, etc. In fact, this product mainly adopts the form of fixed bed and gantry, movable worktable, and welded parts for the bed and gantry. Below are some basic characteristics of gantry drilling machines for everyone?

The gantry drilling machine has 3 CNC shafts and is equipped with heavy-duty linear guide rails. In fact, the workbench of the product can move longitudinally (x-axis) along the guide rail. A linear guide rail is also installed on the gantry beam, and the slider can move horizontally along the guide rail. Motion (y-axis), the slider is equipped with a slider, and the power head is also equipped with a guide rail. The gantry drilling machine can move vertically on the slider (z-axis), and the x, y, and z-axes are all driven by servo motors and ball screws. The spindle adopts a fine spindle, driven by a variable frequency motor, and can be adjusted infinitely according to needs. The spindle BT40 taper hole can be installed with a drill or milling cutter through an adapter, and the spindle box is equipped with a tool release cylinder (gas-liquid booster) for easy tool replacement. Tools can also be equipped with intermediate cooling rods to achieve high-speed cutting. And its characteristics are also reflected in different places. For example, it can be used for cast iron parts such as beds and gantries. After full heat aging treatment, high-temperature annealing at 550 ℃, and insulation for no less than 4 hours, the internal stress can be effectively cleaned. Therefore, the dynamic and static stiffness is better, and the deformation is very small. In addition, the drilling spindle of the gantry drilling machine is driven by a 7kW strong overload spindle variable frequency motor, which has high low-speed torque and can withstand heavy cutting loads. The drilling is strong and the drilling stability is good.

The gantry drilling machine is equipped with corresponding servo motors and servo drives, which have good compatibility, powerful functions, and simple operation. Moreover, the installation accuracy of key transmission components such as linear roller guide rails and fine ball screws is high. For example, a linear guide rail has an installation reference plane. After tightening, check with a 0.04mm feeler gauge and do not insert it; The parallelism tolerance between linear guides is 0.05/1000; The parallelism between the ball screw and the linear guide rail is 0.03/1000, etc. Of course, hydraulic fixtures can also be installed to automatically clamp circular flanges and improve processing efficiency. By adopting a fixed gantry and a movable workbench, the gantry drilling machine has good rigidity and can effectively reduce vibration during cutting, which is beneficial for improving accuracy and tool life. High efficiency, both internal and external cooling, and violent drilling are available. The gantry drilling machine has a fast processing speed, which is 3-5 times faster than ordinary rocker drills. Of course, its characteristics are also reflected in its strong rigidity, convenient use, simple operation, and ease of learning. It is difficult to find and manage drilling workers with old techniques. One person operates multiple devices to achieve machine replacement. This is a good beer manufacturer on the internet, and the company's official website offers a variety of different products.

The above article is about the basic characteristics of gantry drilling machines introduced by the editor. If you are also curious, come and take a look. I believe it will not disappoint you. That's all for today's content. I hope it can be helpful to you.