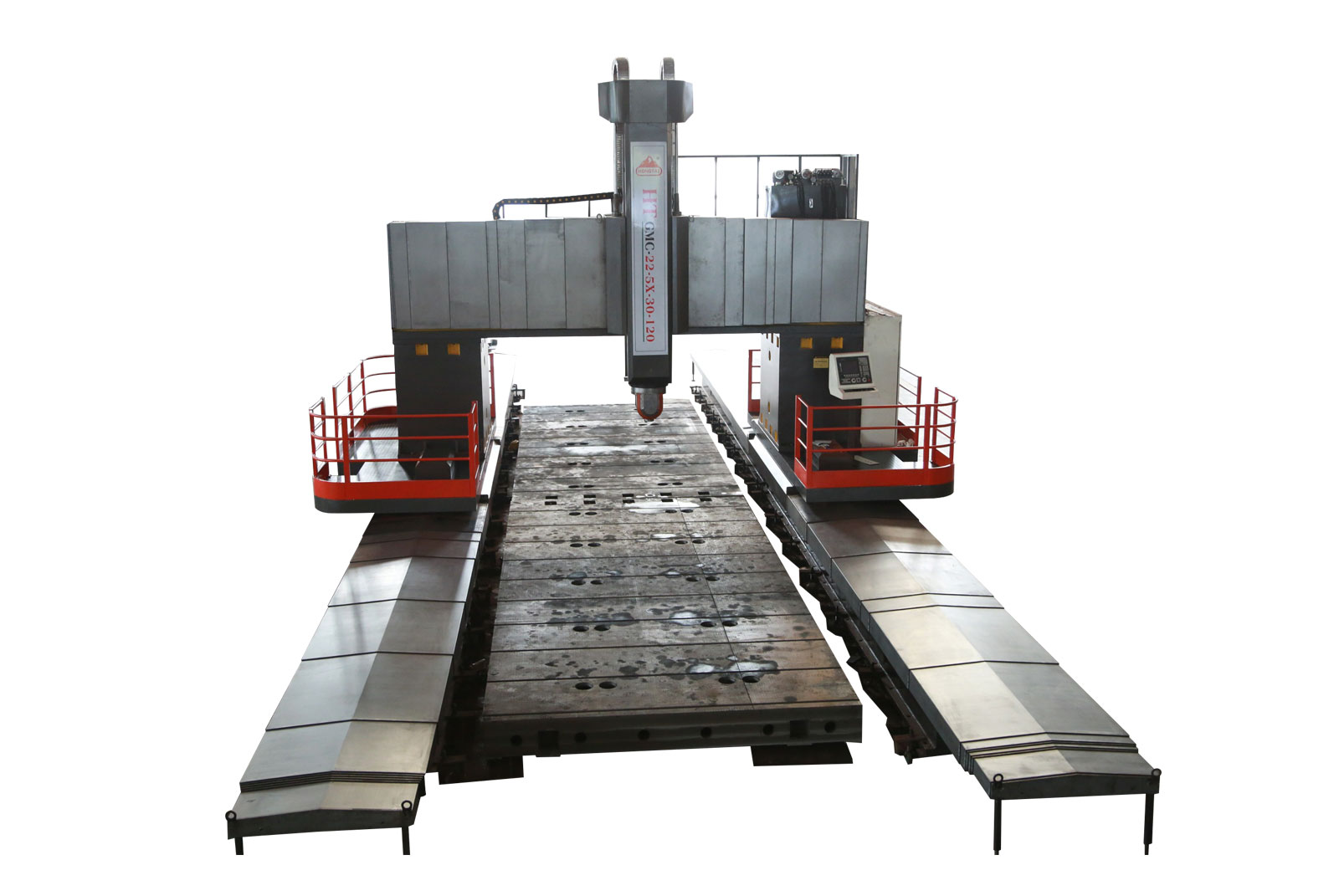

Due to the fact that machining centers are generally developed on the basis of milling machines, they can be called CNC gantry machining centers for milling machines, commonly referred to as CNC gantry machining centers. CNC gantry machining center is currently one of the most widely used and high-yield CNC machine tools in the world. Let's take a look at its main features below.

(1) On the basis of CNC boring machines or CNC machine tools, a built-in internal tool changing device has been added, so that after clamping the workpiece in one go, it can continuously complete multiple processing steps on the surface of the workpiece, and the process is highly concentrated.

(2) CNC gantry machining centers generally have automatic indexing turntables or spindle boxes that can automatically rotate the angle, enabling the workpiece to automatically complete multi plane or multi angle position multi process machining after being clamped in one go.

(3) The CNC gantry machining center can automatically change auxiliary functions such as spindle speed, feed rate, and the motion trajectory of the tool relative to the workpiece.

(4) If the CNC gantry machining center is equipped with an exchange workbench, when the workpiece is processed on the workbench at the working position, the loading and unloading of other workpieces on the loading and unloading position workbench will not affect the normal processing of the workpiece.

The above are the common characteristics of gantry CNC gantry machining centers. Taking this opportunity, starting from the characteristics of CNC gantry machining centers, we will now provide a detailed introduction to the operation process of CNC gantry machining centers.

1. The use of equipment implements a fixed person responsibility mechanism, requiring operators to operate the equipment with an operation certificate. When multiple people operate large equipment, it is necessary to designate a dedicated person to operate it.

2. Operators should be familiar with the main technical performance, structure, maintenance content, and integrity standards of the equipment used.

3. Preparation before work:

(1) Check the transmission system, operating system, lubrication system, pneumatic system, various switch start positions, safety brake protection devices, power stability system, and electrical instructions of the CNC gantry machining center. The above system needs to be complete, correct, sensitive, reliable, and undamaged. The fastened peripheral components and connecting components should not be loose.

(2) Perform lubrication according to the equipment lubrication chart.

(3) Run the spindle and various servo axes at low speed in manual mode.

(4) According to the part processing program table, check if there are any errors in the tool compensation value and key point offset position in the memory table of the CNC gantry machining center system. Retrieve the tool compensation value and zero offset value, and check if they are correct.

(5) When using paper tape input, it is necessary to regularly check whether the paper tape used is damaged and whether the photoelectric reader is functioning properly.

(6) The specifications of T-bolts used for tightening ring parts should be consistent with the specifications of T-grooves on the equipment workbench. During the tense weeks, the strength should be moderate. It is prohibited to apply force to the correction parts of various parts of the CNC gantry machining center.