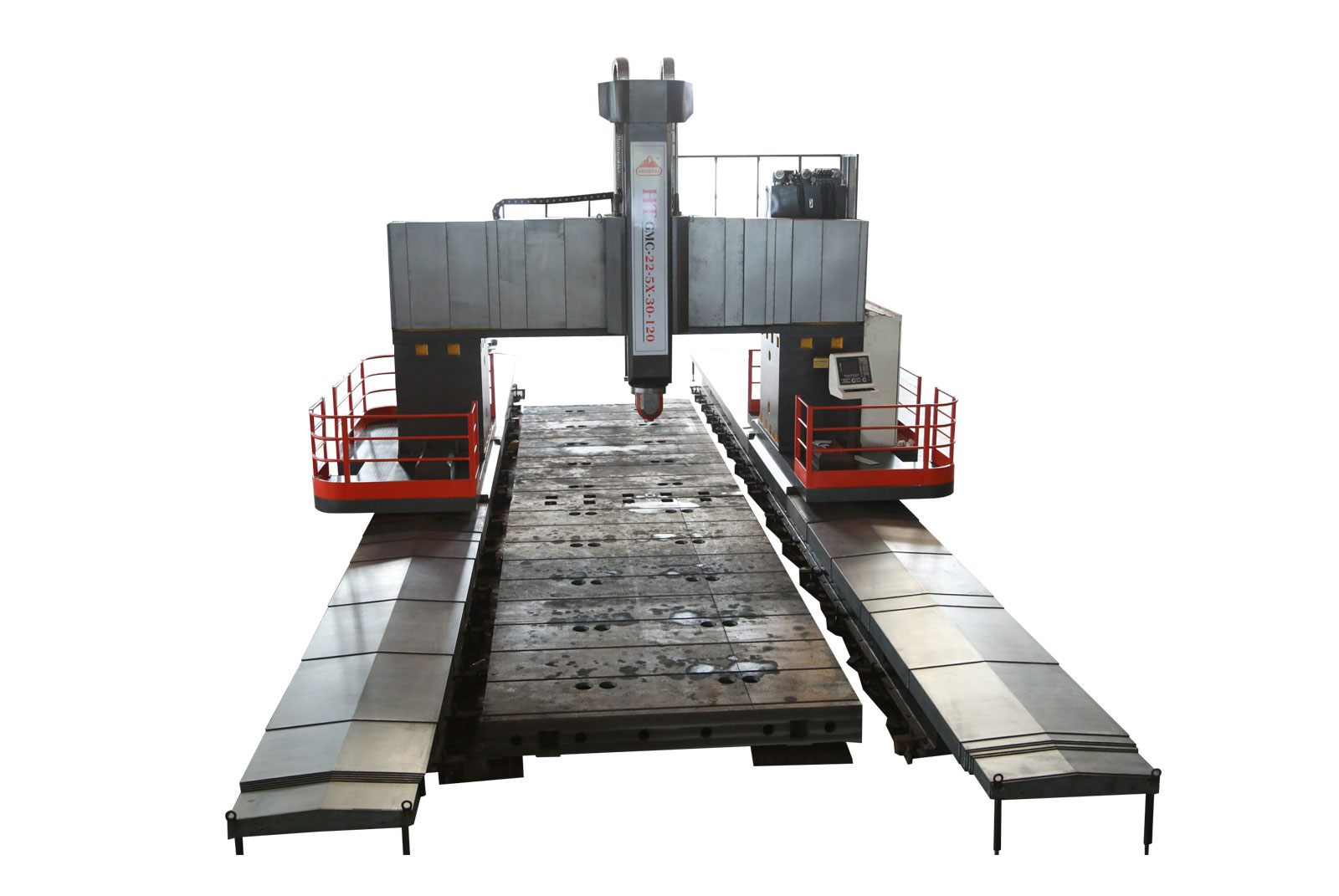

CNC gantry machining center occupies an indispensable position in today's high elite manufacturing industry. It is an automatic machine tool equipped with a control program that can be recycled for machining parts according to the shape and size required by the drawings. CNC planer milling machine/CNC planer milling machine machining center operation and monitoring are carried out in the CNC unit, it is the brain of the machine tool, compared with ordinary machine tools, CNC planer machining center has the following characteristics, to simply understand it.

1, strong adaptability to the processing object, suitable for the characteristics of mold and other products single production, for the mold manufacturing provides a suitable and accurate processing method.

2, CNC machine tool processing accuracy has stable processing quality.

3, can carry out multi-coordinate linkage, processing complex shape parts. 4, when the machining parts are changed, the CNC gantry machining center only needs to enter the number of the program to achieve the processing purpose, saving production preparation time.

5, CNC gantry milling machine itself has large structural stiffness, high precision, heavy cutting, and improved production efficiency.

6, CNC machine tool automation process is high, one person to achieve multiple machines, saving labor costs.

7, CNC gantry machining center is conducive to the modernization of production management, the use of digital information and standard code processing, transmission of information, the use of computer control methods, laying the foundation of computer-aided design, manufacturing and management integration.

8, high reliability.

China vigorously develop the industrial manufacturing industry, CNC gantry machining center for the domestic manufacturing industry add tile, this solution to user needs of the machine tool also solved many manufacturing problems. Let's take a look at the matters that should be kept in mind in the safety production of CNC gantry machining center.

In any case, to do CNC machining, safety production is still a very important standard. We must ensure the personal safety of the producers when producing. There are several things to remember when producing CNC gantry machining centers.

As the operator of the CNC gantry machining center, you need to be familiar with the equipment, understand the performance of the machine, in case of an accident, to solve the problem in time, do not rush, and again, according to the production of different workpieces, according to the relevant regulations prohibit wearing protective equipment, wearing gloves to operate, to prevent screwing the sleeve, the machine's live operation, Must avoid touching the electronic switch with wet hands, do not put some tools on the gantry machine tool, do not open the protective cover when the machine is running, the setting of the tool needs to be the first prototype, to ensure that the program of the CNC gantry machining center is no problem, non-professionals do not remove the stroke switch or other protective switch parts, after the end of the work, The main switch of the control power supply and electrical box of the CNC gantry machining center should be turned off.