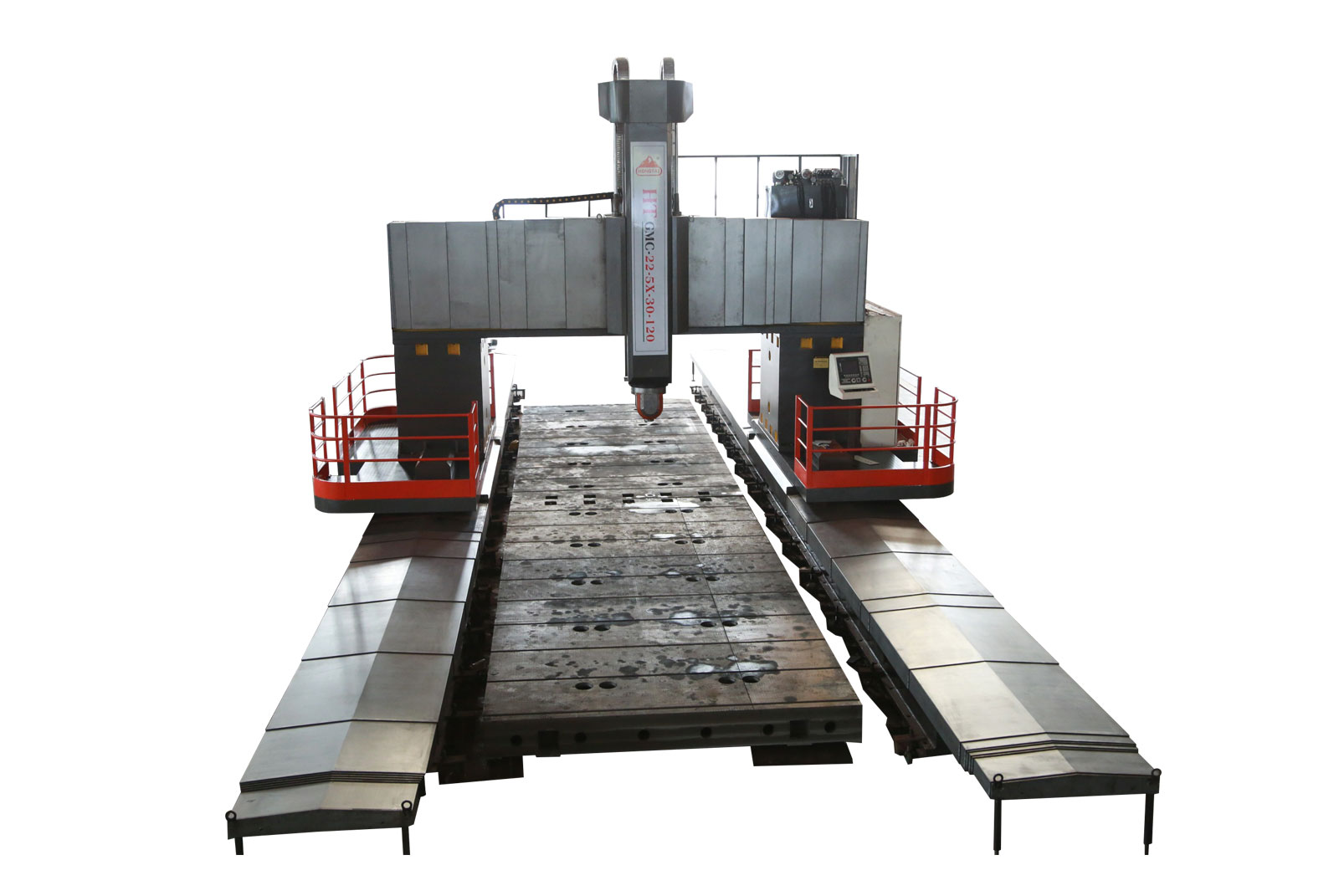

CNC gantry drill is mainly used for drilling, reaming, reaming, tapping and other processing. It is a kind of hole processing machine tool based on CNC drilling. Due to the development of machining center, the vast majority of CNC drilling machine tools have been replaced by machining centers. Automobile, locomotive, shipbuilding, aerospace, engineering machinery industry; especially for large parts of drilling into the sea with rich multi-hole system, such as super long laminated plate, longitudinal beam, structural steel, pipe fittings, etc., drilling should be selected.

CNC gantry drill is a kind of processing machine tool based on CNC drilling. Due to the development of machining center, the vast majority of CNC gantry drills have been replaced by machining centers.But some parts with drilling as the main processing technology still need to be processed by CNC gantry drills, such as printed circuit boards, so there is a certain demand for CNC gantry drills.

Most CNC gantry drills adopt point control, moving along two or three axes at the same time to reduce positioning time. In addition, on the basis of three-coordinate CNC vertical drilling machine, plus turret tool library and automatic tool change mechanism can constitute drilling processing center (drilling center). Drilling center can not only drill, reaming, reaming, tapping and other hole processing processes, but also can be completed with linear and arc interpolation contour control milling.Drilling center is mainly used for processing small and medium-sized parts in the mechanical and electrical industry. CNC vertical drilling machine is developed on the basis of ordinary vertical drilling machine. Can complete drilling, reaming, reaming, tapping and other processes, suitable for the hole distance has a certain precision requirements of small and medium-sized batch parts production.

CNC vertical drilling machine generally adopts two coordinate CNC "ten" type worktable. The machined parts are clamped on the worktable for two coordinate movement (the front and rear movement of the worktable is X coordinate, the front and rear movement of the worktable is Y coordinate), and the vertical movement of the tool spindle or spindle box (Z coordinate) can be numerically controlled, and non numerically controlled. The former uses three coordinate numerical control system, while the latter can use a simpler two coordinate numerical control system. The spindle speed change and tool replacement are not much different from ordinary vertical drilling machines, mostly manual operation. It is suitable for machining porous parts with hole accuracy requirements but not too high. The numerical control system is generally a point control system (there are also linear control numerical control systems), which belongs to the economic numerical control, and the price is cheap.

The characteristics of CNC gantry drill:

1, the coordinate movement is driven by the servo motor, convenient operation, flexible and stable precision.

2, the basic layout is: the sliding seat is fully moved on the bed, single side open, simple and convenient structure, easy installation and cleaning of the workpiece after work, easy maintenance, small footprint, suitable for the processing and production of long parts. 3, the column on the sliding seat and the ordinary rocker arm drilling machine adopts cylindrical column, the rocker arm can be lifted up and down, convenient for processing different heights of the workpiece.

4, the spindle 16 speed, cutting torque expanded dozens of times, Morse cone hole, can be directly installed drill.

5, the valve body adopts the casting structure, can be extended, the user can choose or customize.

6, X axis is the sliding seat, using the German imported reducer, gear, rack, to ensure the stiffness and accuracy of the movement.

7, the bed guide rail without protective plate, to ensure that the frame, grating ruler, electromechanical switch is not affected by the outside world.

8, X axis using the imported original grating ruler, to ensure the X axis positioning accuracy.

9, the use of Siemens 802D numerical control system, AC servo and rare earth permanent magnet motor, excellent performance, high reliability, safe and durable.

10, ultra-thin LCD display, oil-proof keyboard, beautiful and generous.